Let's Overstock Inventory and Overhire people - Part 1

We'll talk about how inventory reordering works, the fundamentals or it and a framework to use in your business.

Hey folks 👋, Bala here with another issue of OpsWorld. If it's your first time here, we generally write about technology and how it impacts the world of Operations.

Before we begin,

OpsWorld is created by the team at ZORP. In simple terms, ZORP is the Operations Infrastructure to help you move from Spreadsheet Ops to Six-sigma level.

This post is Part 1 of understanding how Inventory Reorder Levels work. By the end of it, you should understand how inflows, outflows work, how can time impact the whole thing and how to account for variability in each of these parameters. There are some advanced concepts around Inventory Oscillation which are important but can be pushed to the next issue.

This post will help you if you do any of the below:

You manage inventory in your business

You hire workers to run your operations

You work on supply chain

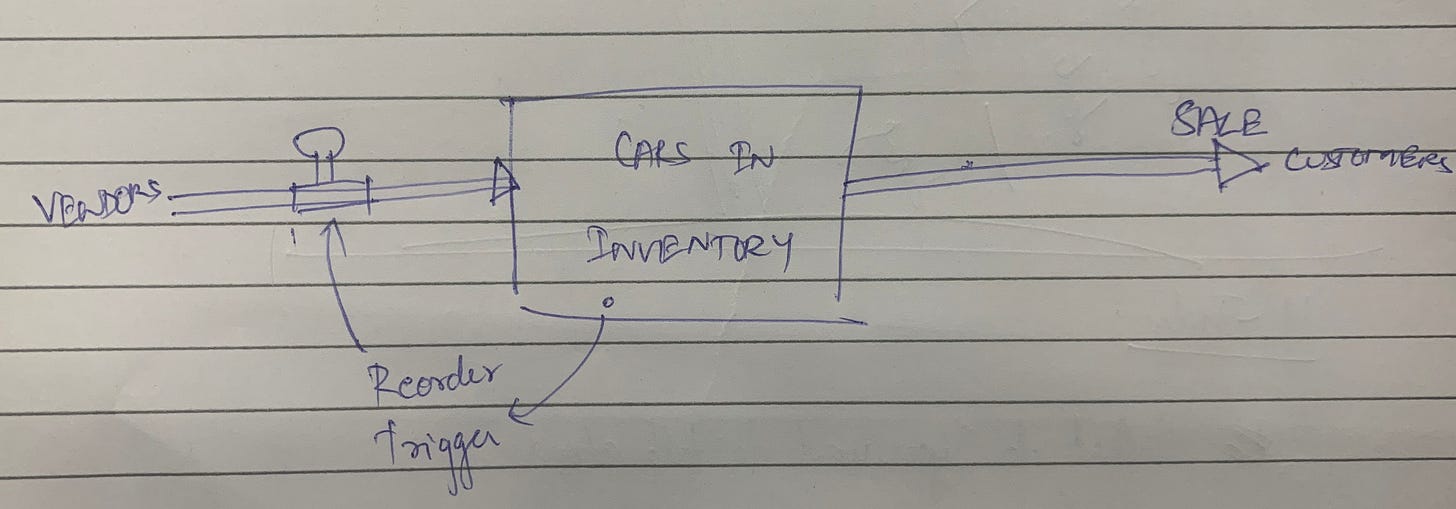

It’s good to take real-life examples for clarity. But remember that the assumptions will change for different businesses. So, use wisdom. For this exercise, we will assume that we’re working with a car dealership. Your inventory are the cars. Your inventory has an inlet and an outlet. Here, inlet represents the inventory coming in and the outlet represents your sales/returns.

The objective here is to maintain a specific number of cars in the inventory so the dealership can serve its customers efficiently. At the same time, we want to keep the minimal inventory at any point in time coz it’s going to cost us. This is called an inventory holding cost. It’s money that’s better spent elsewhere.

I typically like to structure them in the form of a target metric and a control metric.

The target metric here is to always maintain a minimum inventory and the control metric is the cost.

Let’s talk about why you need a minimum number of cars?

The assumption is that you need to deliver the cars which the customers order. So, you need to have the stock else might result in bad customer experience and even lost sales.

But if you order too many, the car is going to simply stand in your garage which leads to investment that is not giving any returns. There is a cost of storing that car at the garage (garage has limited space) and the investment could have been made to purchase a different model that has demand.

Now, let’s put these together and understand how this looks practically.

Let’s break this down.

Sales Variations

In the real world though, your sales is not always steady. There’s plenty of variability in there could be because of a festival season or better promotions or just an economic downturn. You need to make sure that these variations are accommodated in the inventory reorder model you’re designing.

Let’s see how you can accommodate for that variability.

The part that is not obvious to us who usually work with averages is that in this case, you cannot work with averages but the exceptions.

What is the acceptable level of variation that your inventory needs to accommodate for? A good way to do this is to take in to account your typical variations and set a threshold. Variation can be defined by a metric called `Standard Deviation`. It is the normal fluctuation you see from the average sale on a typical day. For example, if your average sale per day is 12 cars, you might see that most of the days, it might range from 9-15. Sometimes it could get to 20. But the typical range can be mathematically defined using Standard Deviation.

An acceptable metric to reserve inventory is to keep, at any point in time, a 2*standard deviation number of cards. This ensures that unless absolutely critical times, you will be able to keep enough inventory in hand. Depending on your variability, you can push this to 1SD or 3SD. Choose what is right for your business.

Procurement Variations

Similar to the sales side, when you order the cars, you don’t get them immediately or at the same time. They take time. So, just because you order the inventory today doesn’t mean you will have cars to sell tomorrow. You need to order them ahead of time. Your objective here should be to order them at the right time so that when you receive the inventory, it just covers the minimum inventory you require.

This is called Just In Time (JIT) inventory setup.

Just In Time inventory can be defined as having the right amount of stock at any time so there’s no excess inventory being held or less inventory that you need to forego sale.

A good example of this is flight tickets. You might know that flights always oversell their seats. This is because, they always see a few fliers dropping out at the last minute. Their target metric is to fill up the seats. Their control metric is that they don’t want to forcefully cancel a customer (leads to bad CX).

Let’s put a rough Framework around this

Based on the above fundamentals, let’s define a few variables to take care of our reorder levels.

Demand Forecasting

This is the expected sales over the next days, week, month, year.

Lead Time

This is the time taken to get the products once you place an order

Safety Stock

This is the stock level you must have at any point in time so you’re covered. This will handle any sudden spikes in your demand or delays in your procurement. Your stock should never go below this.

How to calculate the safety stock? Look at the Standard Deviation calculation we did earlier. The following generic formula should work accommodating both the sales variations and the lead time variations.

Safety Stock = Z * sqrt((StdDev Sales^2 * Lead Time) + (Avg Sales^2 * StdDev Lead Time^2)).

Here, Z represents something called a Z-score. This is basically your confidence level. With a smaller Z-score, you will probably under invest in inventory but will be liable to more stock outs. With a larger Z-score, you will have more inventory that you will be covered even in bad economic scenarios but you will pay more for holding your inventory.

Reorder Level

The quantity at which you should be ordering inventory again. This is set in such a way that when you order something on T1 and it arrives on T4, on T4, your stock should have hit the safety stock level.

Reorder Level = ( Daily Demand * Lead Time ) + Safety Stock

Now, we can’t reduce this whole thing to one single formula. The obj of this post is to set the fundamentals for how inventory reordering works. You will want to fit this to your existing business and see what’s applicable.

Did you find this useful? If so, consider sharing it in your network. If there is a specific topic in Operations that you want me to address, do let me know in the comments.